RSB

The RSB seal type is similar to the RSA type, but on the dynamic side, it presents a multifunctional double lip which:

- Reduces stick-slip effects thanks because it

Keeps oil between the secondary lip and the

main one - Stops any external impurities

- Faces the material shrinkage at low temperatures

- Acts as a stabilizer.

-

High wear resistance

-

Superior sealing effect with the secondary lip

-

Secondary sealing lip provides extra protection against the ingress of dirt particles

-

Wide range of dimensions

-

Simple groove design

-

Easy assembly into closed grooves

Construction machinery, fork-lift trucks, injection moulding machines, agricultural machinery, loading platforms and standard cylinders.

Easily assembled into closed grooves according to the minimum diameter values that are given in the below table. Open grooves or special assembly tools should be used for the values that are outside this table. It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation the sealing element must be oiled with system oil.

| Material | Code |

| PU 93 Shore A ± 2 | PU C0 |

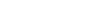

| Surface roughness | Ra | Rmax |

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm |

| Groove Base ØD | ≤1.6 μm | ≤10 μm |

| Groove Flanks | ≤3.2 μm | ≤16 μm |

Permissible sealing gap

| S max (mm) | |||

| t=(D-d)/2 (mm) | 150 Bar | 250 Bar | 400 Bar |

| t≤5 | 0.30 | 0.20 | 0.15 |

| t>5 | 0.35 | 0.25 | 0.20 |

OPERATING CONTITIONS

| Media | Mineral oils (DIN 51524) | HFA HFB | HFC |

| Temperature | -35 °C +100 °C (with peaks +110 °C) | +5 °C +50 °C | -30 °C +40 °C |

| Pressure | ≤400 bar | ≤400bar | ≤400 bar |

| Speed | ≤0.5 m/sec | ≤0.5 m/sec | ≤0.5 m/sec |

Minimum diameter values for closed type of grooves

| (D-d)/2 (mm) | 4 | 5 | 6 | 7.7 | 10 | 12.5 | 15 |

| d min (mm) | 25 | 30 | 40 | 50 | 80 | 100 | 105 |

Would you like to know more about this product?

E-mail

info@intramark.hu

Phone

+36 52 540 555

+36 20 913 4498

Nyitvatartás

H-CS: 8:00 – 16:30

P: 8:00 – 16:00

Intramark HQ

4031 Debrecen,

Köntösgát sor 10.