Technology

INTRAMARK

Technology

High precision measuring

- We introduced high-precision seal and gasket measurement capabilities in 2025.

- An Irish made optical inspection machine was installed at our headquarters.

Material science

- We have developed great material knowledge through the years

- We have an elastomer compatibility calculator on our website, that can tell what is the tolerance of the materials that seals are made of in different enviroments

Diagnostics

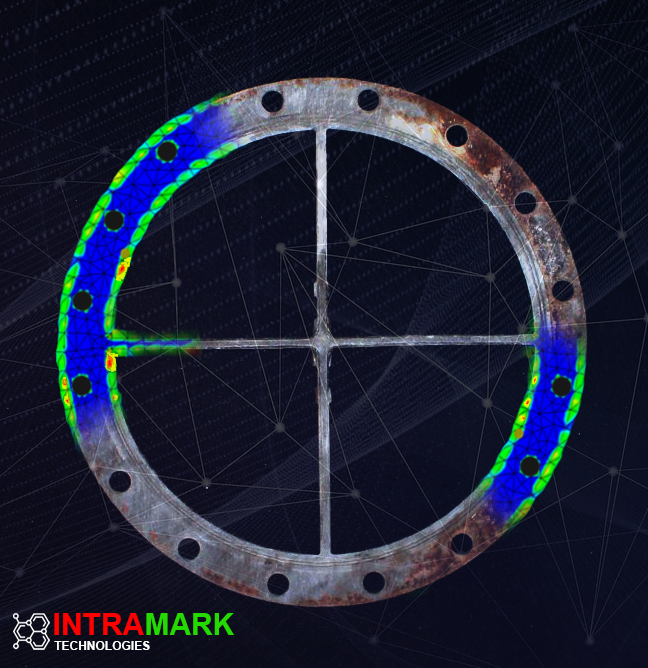

- Scanning of damaged gaskets

- Our scanner is able to scan damaged or partially damaged gaskets up to 1500mm x 1000mm, and after scanning, we can quickliy recreate the original shape of the gasket in CAD software.

Oil pressure testing

- Pressure testing of hydraulic systems

- Our newly acquired hydraulic cylinder test bench is able to pressure test cylinders, and different hydraulic systems

- After testing we can provide a printed report for our customers

Engineering the Technology Behind Sealing

The sealing solutions provided by Intramark are supported by advanced technology and extensive material expertise. Our specialists always recommend the most optimal sealing material and profile based on the application environment and specific requirements. This approach ensures the use of durable, high-performance seals that are fully adapted to industrial operating conditions.

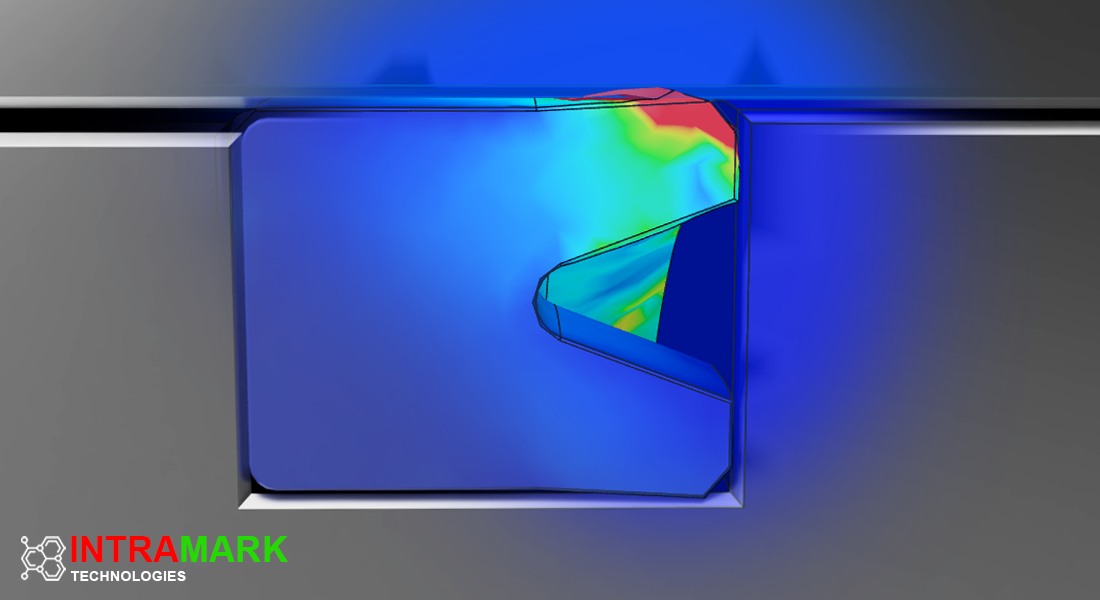

Seal measuring

It is often the case that our partners are only able to provide an damaged flat gasket. For such situations, we use a specialized scanner capable of digitizing flat gaskets up to 1500 × 1000 mm, even if they are damaged or partially missing. After scanning, we use artificial intelligence and reverse-engineering to accurately reconstruct the original gasket geometry in CAD format, which can then be directly used by our flat-cutting system.

Seal measuring

At Intramark Ltd.’s Debrecen plant, an InspecVision Planar 43.100 optical measuring machine from Northern Ireland is now in operation. The system provides fast and accurate 2D/3D measurement for parts up to 810 × 520 mm in size, 50 mm in thickness, and 25 kg in weight. It has a measuring speed of under 0.25 seconds. The machine uses an ultra-high-resolution industrial camera and the InspecVision software suite for 2D/3D inspection, SPC, reporting, and reverse engineering.

Material science

Thanks to the continuous development of our knowledge base, our team always recommends the most suitable material and seal profile for each sealing requirement. With the elastomer compatibility calculator available on our website, you can also select the appropriate seal material for the medium to be sealed.